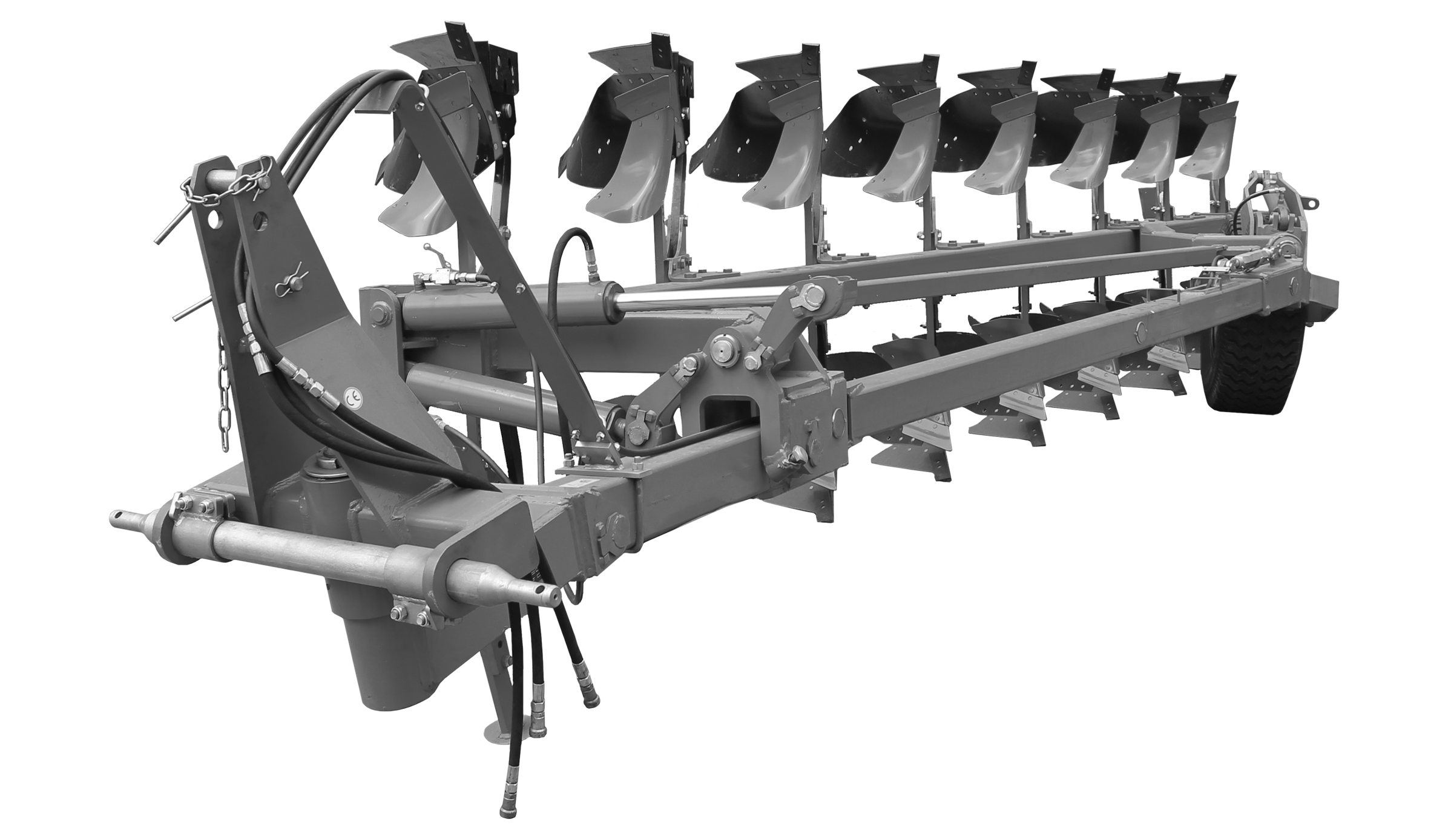

Description

The PRXM series is a new generation of plows produced by JSC “Moldagrotehnica”, which are based on new working bodies, production of “BELLOTA HERRAMIENTAS” JSC – Spain.

The transition to these organs was determined by market demand for more advanced plows, which would meet the latest requirements and that could compete with the most famous international brands, specializing in the manufacture of plows.

Proceeding of these conditions, JSC Moldagrotehnica has established cooperative relationships with well-known Spanish company «BELLOTA HERRAMIENTAS JSC», which produces working bodies, of German high-quality steel, for most world manufacturers of agricultural machinery (Vogel&Noot, Lemken, KUHN, etc.).

The choice of a PRXM reversible plow means:

- Assurance of the qualitative soil structure, an efficient deepening and distribution of plant debris;

- Equipped with a wide range of adjustments;

- Ensuring low energy consumption;

- Increase productivity of unit by increasing its speed of work;

- Increased resistance in different climatic zones.

The choice of a PRXM plow means obtaining high yields and optimizing financial results, which start from the high quality of plowing.

THE PROCESS OF PLOW TURNOVER

The reversible plow differs from simple plow by its special construction, which contains two rows of working bodies, right and left, and thanks to the exclusive options that are not found in ordinary plows.

The reversible plow provides both type of plowing: to and from moldboard, only the construction of this plow has the option of turnover. This means that at the end of furrow, in the area of return, plow is rotated at 180˚ and starts a new furrow, adjacent to the previous, without traveling around the already plowed portion.

Axis of rotation of the plow (1)

At the bottom of the plow mounting system is mounted an axis which slides on two conical bearings. In the back side of mounting system, this axis is rigidly fixed to the main frame of plow. Namely this axis provides the rotation of plow through the hydraulic forces.

Hydraulic cylinder (2)

The turning of plow is made with the help of the tractor hydraulic system, which drives the hydraulic cylinder with dual action, mounted on the mounting system of the plow.

This cylinder ensures a fast and at the same time smooth turning of the plow. Because the full rotation constitutes 180˚, the cylinder must perform two turns in a row. To ensure this working process, plow is equipped with a local hydraulic distributor, which directs the hydraulic cylinder.

Hydraulic distributor (3)

This distributor is designed to drive the hydraulic cylinder. On one drive of lever of the tractor hydraulic system, distributor causes 2 working turns of the hydraulic cylinder of the plow, which ultimately provides full plow turning.

Moreover, between the operating moves of the hydro cylinder there is a 2-second pause. At the release of the lever at the moment of pause, distributor will stop the cylinder work and in the result the plow will remain turned at the 90˚ and will be willing for fixing in the transport position.

In parallel with that, hydraulic distributor ensures slow and uniform rotation of the plow.

Advantages:

- High productivity;

- Maneuverability;

- Reducing fuel consumption.

ADAPTATION OF PLOUGHS TO VARIOUS TYPES OF TRACTORS AND ARABLE CONDITIONS

PRXM is a plow which meets the latest requirements of the consumer: tough, reliable and easy to service.

Due to the large distance between the bodies (780 mm), and to the great distance from the supporting plane and the underside of the chassis frame (720 mm), the work is guaranteed without clogging the working bodies, regardless of the amount of crop residues.

* Adjusting the plow in order to adapt to different types of tractors.

Plow is equipped with a mechanism by which, in dependence of the distance between the wheels of the tractor, can be moved to the right or left from the axis of the tractor. This mechanism also serves for setting the angle of attack depending on the working width of bodies, which is also adjustable.All these operations are done by increasing or decreasing the adjustment rods A and B.

* Adjusting the working width.

Each body is adjusted in part 28, 32, 36 and 40 cm. Adjustment is made by changing the holes of the support of body on the frame of the axis. Along with changing the working width of the bodies also is adjusted the angle of attack by adjusting rods A and B, which acts on the entire frame. Namely this control allows adaptation of plow to any type of soil and climatic conditions.

* Leveling of plow frame from land surface.

There are certain specific conditions for all types of plows. One of the conditions is that in the working process, the frame of plow must be horizontal from ground.

In the case when in working process the tractor is moving a half in the furrow, there is need to establish the plow horizontally from ground. This can be made by adjusting the rods of the mounting system of the tractor, as is typical for most plows and is considered a difficult adjustment, uncomfortable and established by several attempts.

A more advanced solution, which is implementing on all the plows produced by “Moldagrotehnica”, is equipping plows with adjustment rods (1) for horizontality adjustment from ground, without further adjustment of rods of the mounting system of the tractor.

Useful benefits from adjusting working width:

- Adaptation of plow to the available traction power;

- Save time and reduce fuel consumption;

- Increased speed of working on steep slopes;

- A qualitative and effective plowing regardless of the vegetable waste quantity;

- Processing of fallow land, long time unprocessed;

- Quick adaptation of plow, regardless of tractor track.

CONSTRUCTION OF WORKING BODIES

Body construction:

- cultural moldboard and its extension (1):

This type of moldboard ensures an effective return of swath and intense fragmentation of boulders. As the blade fulfills an active working regime, it is protected with shin (2), which protects it from various obstacles and intensive wear.

- blade (3) and chisel (4):

Besides the fact that the chisel ensures the protection of blade, it is also characterized by using in two shifts. When chisel tip is worn at maximum, chisel is turned at 180˚ and is used for a period approximately equal to the first exchange.

- angular moldboard (5):

It’s a tool placed on top of the moldboard, which provides efficient turning and deepening of plant debris. Angular moldboard manifests efficiency especially in cases when land is covered intensively with plant debris.

- landslide (6):

In working process, this tool is permanently under load. From constructive point of view, there are 2 types of landslide: right and left. To increase the period of exploitation, the construction provides that in the moment of maximum wear of landslides, to change them with places: right landslide on left body and vice versa. In case of replacement we’ll get the used side of landslide inside of body, and the unused side, outside of body, which is considered as the active part of it. These changes do not influence the technical qualities of the plow or the quality of plowing.

All these components, including the support of bodies, are produced by “BELLOTA HERRAMIENTAS” JSC and are characterized by:

- Fabrication of boron-containing steel;

- Maximum wear resistance;

- Long-term of exploitation;

- Effective turning of swath;

- Minimum resisting.

PROTECTION OF RACK BY SHEAR BOLT

In order to ensure the protection of body from obstacles and overload, the rack is equipped with a shear bolt with a 16 mm diameter, which breaks when the pressure on tip of chisel is exceeding 3000 kg.

WHEEL OF TRANSPORTATION AND FOR ADJUSTING PROCESSING DEPTH

* Support and transport wheel

Is fixed on a special support with shaft and serves to regulate and maintain the working depth, and for the movement of the plow in transport position. Depth of processing is fixed with a screw mechanism which is fixed depending on the necessary working depth.

Passing of the wheel from left side to the right, at the moment of plow rotation, is done automatically, slowly and without spontaneous strikes, because the wheel is maintained by a damper.

Slow passing of the wheel at the moment of plow rotation is one of the main advantages that can have a reversible plow. In the situation, when wheel passing is done with strikes, in frequent cases are caused damage to both parts, to plow and to tractor mounting system.

* The passing of plow in transport position.

The passing of plow from working position to transport position is made very quickly without too much effort and difficulty. For this, the wheel is manually fixed in the transport position.

To provide a good maneuverability the bracket of the wheel is mounted on a special axle that allows copying the trace of the tractor at the moment of turning. This mechanism allows both rear and front motion.

* Additional fixation in the transport position.

To ensure the rigid fixation of the plow to the mounting system at an angle of 90˚ to the transport position, the plow mounting system was equipped with a fuse, which is manually operated after the plow has been set at 90˚, with the help of hydraulic system.

This mechanism means the progress in producing of reversible plows of new generation. It provides:

• Uniform working depth;

• Slow passing without spontaneous strikes;

• Transportation without difficulties regardless of the road structure;

• Maneuverability and efficient steering;

• Elimination of counterweights at the front of the tractor.

Choosing a PRXM reversible plow means:

- High productivity;

- Functionality;

- Quality of plowing;

- High yield;

- Fuel and energy savings;

- Work in different conditions and climatic zones;

- Work with different types and brands of tractors;

- High wear resistance.

Reviews

There are no reviews yet.